E-BEAM IRRADIATION

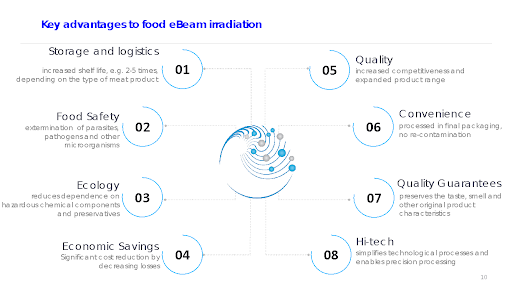

Irradiation technology can greatly help with food preservation non-chemical treatment of microbiological containments – hygienic food; longer shelf life Using eBeam irradiation treatment is one of the most versatile and cost-effective methods to clean food of contaminants (bacterial, insect, fungal, etc.) without changing its temperature taste, color or texture. Sometimes it is referred to as “Cold pasteurization”.

Energy waves destroy bacteria and microbes – ridding food of risk of bacteria harm while translating into much longer shelf life. No need for chemicals, no side effects to human consumption. Irradiation works on packaged, pre-packaged, fresh and frozen foods. It eradicates insect infestations, larva, bacteria, virus and pathogens. It also inhibits sprouting in onions, potatoes, grains, etc. It is a widely accepted method where the precision control and cost of associated machinery needed to produce process has come down to make it viable for food processing. Food produce where irradiation is commonly used ranges from fruits and vegetables; fruit pulpers and juices; grains; pulses; nuts; onions; potatoes; meat& fowl; seafood & fish; spices; teas, etc.

Irradiation energy waves disrupt DNA of pathogens

Irradiation is a widely accepted method for bringing the highest standards of hygienic control to a wide range of foods.

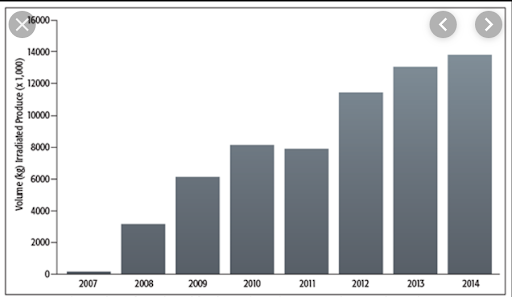

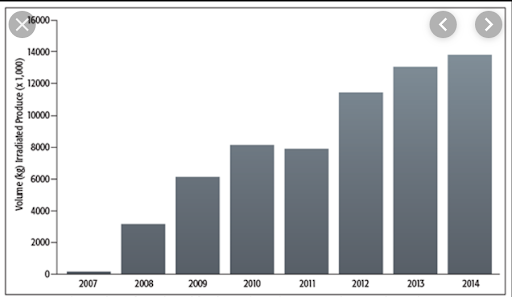

Imports into the USA that have been irradiate is increasing every year

At USDA request, India has long used Gamma irradiation facilities to support Mango exports. eBeam Accelerators are the next generation of technology, allowing for more versatile, higher volume of food processing and can be applied to US imports of Indian rice, mangoes, shrimp, etc.

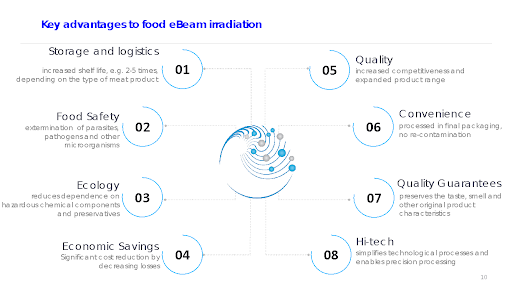

Why e-beam is a preferred technical approach?

In recent years, ionizing radiation treatment has become the most versatile and cost-effective method for solving problems among competing post-harvest conservation methods. “Figuratively speaking, eBeam technology is the smartphone of today, while cobalt-60 technology is the rotary dial phone of yesteryear.” Food Safety Magazine, May, 2018

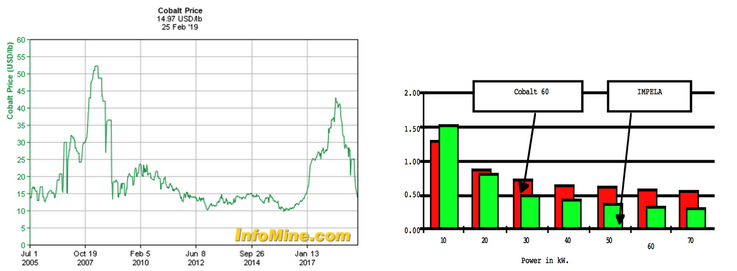

Drawbacks in using Gamma Cobalt 60 verses those solutions using eBeam accelerators a

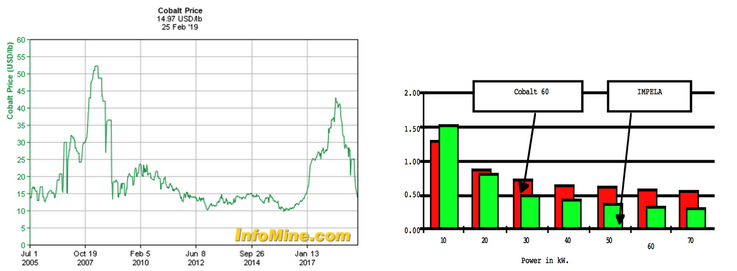

- The increasing costs of acquiring, shipping, storing, and replenishing radioactive cobalt-60.

- Slower processing throughputs and inability to “turnoff” radioactive material.

- Rising security concerns associated with managing radioactive isotopes.

- Consumer reluctance for radioactive materials associated with food chain.

Volatility in Cobalt 60 prices, comparison of overall processing costs

X-ray technologies have a narrow application

Because of the greater penetrating capability of X-rays, it may be used for processing of relatively thick or dense products. For situations where only a shallow penetration is needed and where rapid conveyor speeds can be used, eBeam provides a higher output at lower cost per unit, plus better-quality control.

eBeam technological advantage

- More cost effective,

- faster through put rates,

- safer technologies, environmentally cleaner

- with appropriate software platform extensions, it can be used to maintain the highest qualities, large quantities

The differentiators of e-Beam technology

We supply accelerators engineered with highest quality, but are also produced at a reasonable Capex price, comparable to Gamma ray facilities. Integrated state-of-the-art hardware with precision software platform and diagnostic tools are used to assure irradiation of various food groups is accomplished with highest precision avoids altering of food taste, color or other damage.

Food processing is chemical free – there is residue on food. Moreover, there is no change in the temperature or moisture consistency to the food product. Energy simply passes thru packaging and product.

Adtingo is pursuing a technology transfer scheme to localize production of accelerators under a “Make in India” scheme – jointly owned by its Indian subsidiary to produce accelerators/knowledge transfer.

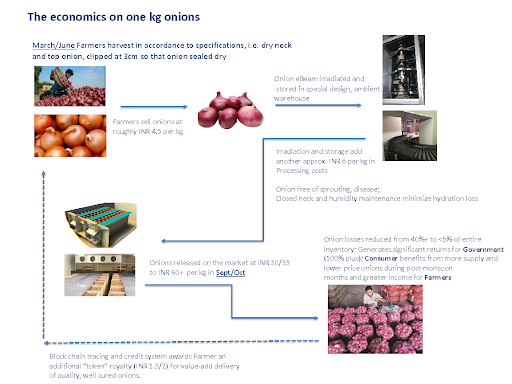

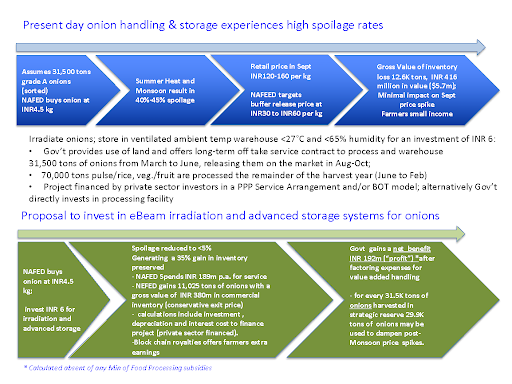

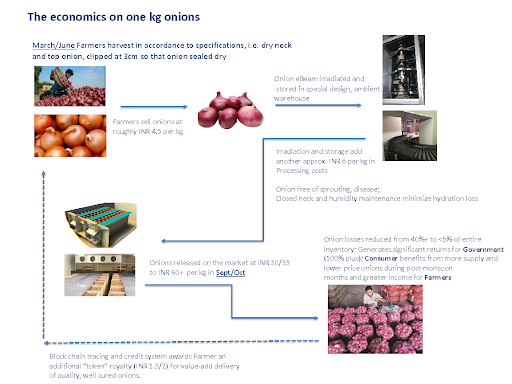

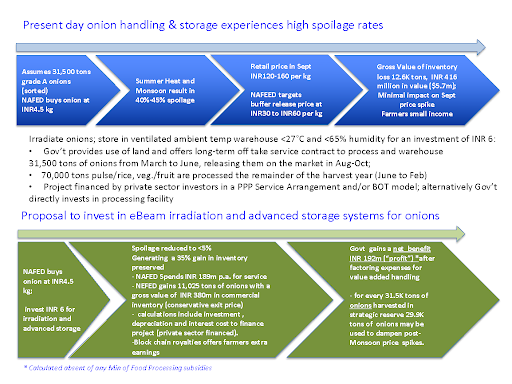

After a two year due dligence exercise, the Indian Department of Atomic Energy selected Adtingo’s accelerator design to be its partner in launching eBeam accerator irradition in the Indian market, launching a show case project in partnership with NAFED for a 100,000 ton p.a. onion and pulses facility outside of Delhi.

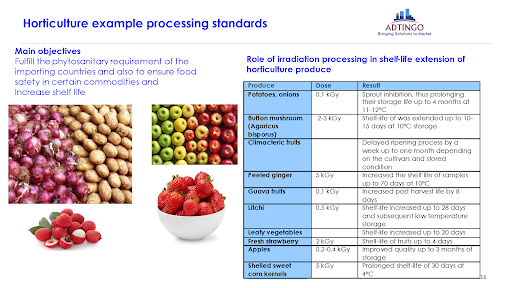

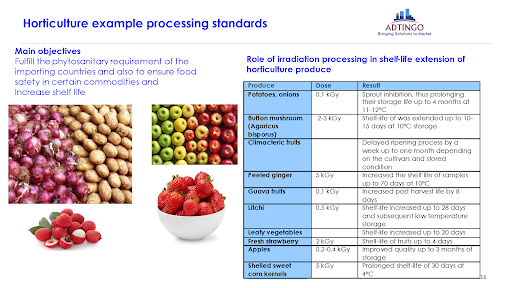

Fruit, vegetable, tea and spices irradiation indicative impact

Anatomy of an integrated processing facility – DAE/NAFED/ADTINGO onion joint venture in Delhi.