RAS TECHNOLOGY

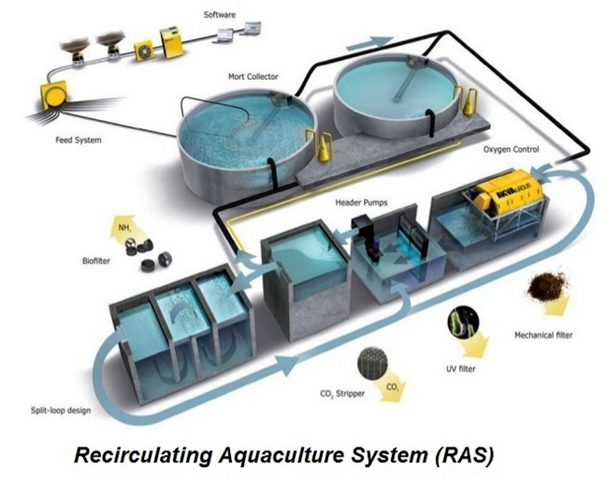

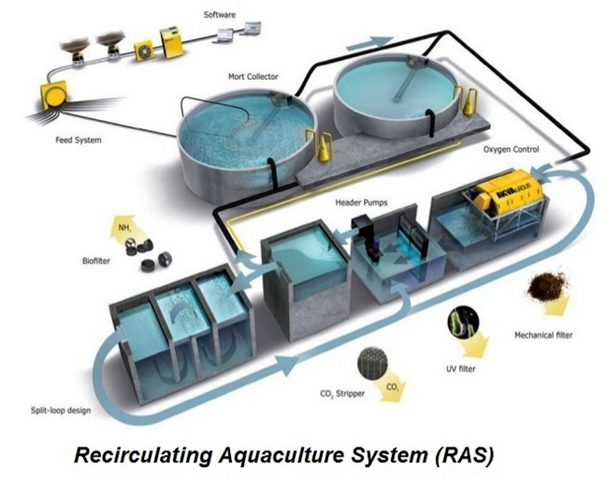

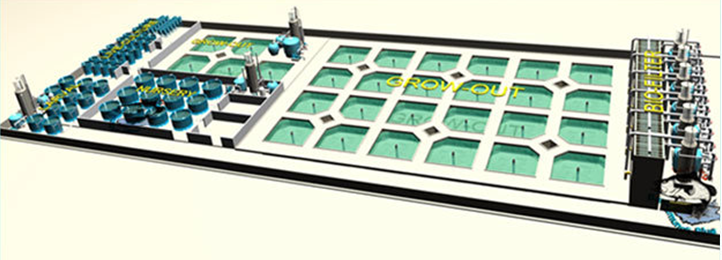

Recirculating Aquaculture Systems (RAS) allow fish to be farmed in tanks instead of open-air ponds, irrigation tanks etc. These systems allow high-density fish production within a breeding environment that is controllable by the operator of the facility. The filters of the recirculating system clean and recycle the water, sending it back to the tanks. New water is only added to the tanks to compensate for water lost due to splashing and evaporation, and to replace that used to remove waste materials.

RAS is an advanced invention which not only protects the environment, but also saves water, reducing environment pressure. In conventional pond, water needs to be filled up and water flow is necessary for fish’s survival. Besides, the conventional aquaculture causes pollution to the environment, because all kinds of pollutants and wastes will sink to the pond bottom, while the pollution discharge effect is excellent in RAS.

RAS is safer and healthier compared to conventional aquaculture. On the one hand, the fish will not be affected by temperature, because heating & chilling can be done as required. On the other hand, fish will grow better with less disease and pollution that is why RAS has a higher culture density.

RAS is a cost-efficient choice for aquaculture. RAS is more profitable, as the Return On Investment (ROI) is much higher than the conventional aquaculture. The water is recirculated, the occupied area is reduced, Feed Conversion Ratio (FCR) is optimized, man power requirement is lower, the culture-cycle is shortened and the fish output is much higher and better in quality. Thus, high value fish can be grown for domestic & export markets and the aquapreneur gets much higher returns.

WHY RAS TECHNOLOGY

The main advantages of Recirculating Aquaculture Systems are easily quantifiable. The first is that they require far less water than conventional systems. Since RAS farms recycle most of their water, they consume much less, making them particularly suitable for areas with limited water reserves.

A correctly designed and operated recirculating system requires a minimum daily water intake, enough to clean the filter residues and to replace the water lost by evaporation. This allows farms to be constructed in areas where groundwater is limited and even in urban areas where chlorine-free municipal water is used.

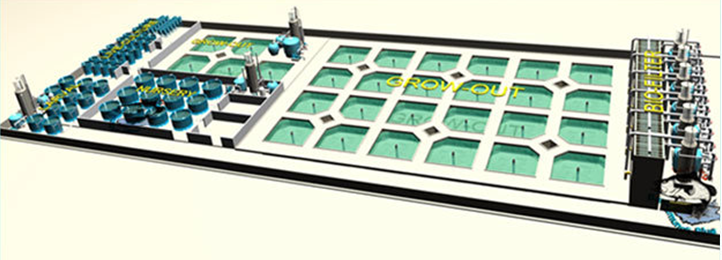

The second advantage of RAS systems is that they require far less surface area due to the much higher stocking density. In conventional pond aquaculture, the stocking density cannot exceed 10kg/M3 where as in RAS it can exceed 40 kg/m3 depending on the species; therefore, a recirculating system can be located in areas where large amounts of flat land (to build ponds) are not available. These facilities can also be located in areas where the land may not contain water, or in urban areas or empty facilities (warehouses) that can be converted into farms.

The ability to control the water temperature is the third advantage of RAS farms. Due to the reduced water requirements, the recirculating systems use little water, so the farmer can control the water temperature (and the growth rates of the fish stock) to produce certain species of fish that normally could not be raised in a given geographical area. It also allows the water temperature to be maintained at the optimal level to maximize feed conversion and ensure optimal growth. In addition, growth can take place year-round, which maximizes production and allows rapid product turnover.

The fourth advantage of RAS systems related to water is quality control. By maintaining the dissolved oxygen at optimal levels, this technology ensures that fish have better feed conversion and reduced stress, resulting in improved resistance to disease, less food waste and higher growth.

Another important advantage of these types of systems is that fish farming in enclosed facilities guarantees excellent protection against adverse weather conditions and predators. By being able to control the breeding conditions at all times, the fish farmer no longer has to worry about a cold wave killing the larvae or the low oxygen levels during the summer.

Finally, it is important to note the environmental advantages, such as the absence of leaks and controlled discharge of waste, since nearly all the water introduced into the system is reused, and less waste is produced compared to conventional systems.

- Fully controlled environment for the fish

- High densities and productivity with easy monitoring of fish

- Good control of water with low water use.

- Efficient energy use

- Efficient land use

- Optimal feeding strategy

- Easy grading and harvesting of fish.

- Full disease control

- Can be designed for species

- Less labour intensive

- Good control of wastes

ADVANTAGES OF MODULAR RAS

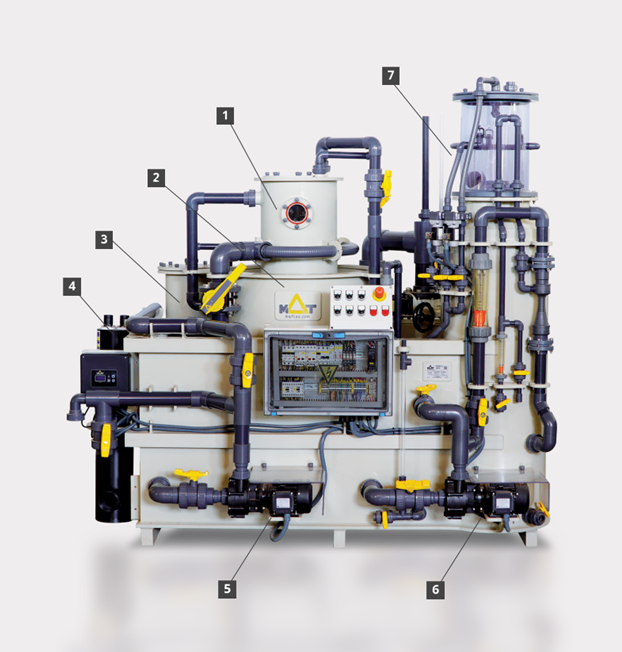

Save on Engineering Costs – Engineering a RAS system from scratch can be an expensive proposition. With a modular system the majority of the design work has already been done. It’s simply a matter of plug & play.

Shrink Project Timelines – With less engineering and design required, projects can ramp up quicker and get finished faster.

Easily Replicate a System – Business is booming and you’re looking to expand – either at your current site or perhaps even in a new market. Great problem to have, right? If you’re using a modular RAS system, you can simply duplicate it to meet your production goals. Not only will it save money up front, but your existing staff already knows the new system front and back, making things that much easier when the system comes online.

Streamline Maintenance – Standardized systems make it easier for maintenance engineers to learn the components inside and out and keep things running right – and to impart their knowledge to technicians to ensure deep understanding of how things run. In addition, with a modular system you can also reduce your spare parts inventory.

Improve Operator Performance – Similar to maintenance above, modular systems mean less training for your staff – and that translates into fewer operator errors.

Minimize Risk – Using a series of modular RAS systems provides built-in resiliency and helps minimize the risk to your business. If one of the systems goes down, it won’t wipe out your entire stock of fish.

Simplify Planning – Using a modular system makes it easier to spec out ancillary aspects of a project. For instance, knowing the energy required to run a certain size module makes it simple to calculate your requirements for a solar panel array or backup generator. Or if you need to expand production, it’s easy to calculate your land or building needs.

Diversify with New Species – If your business has more than one modular system, it enables you to test out a different species while continuing to cultivate your target species in the other systems.

Finance Business Investment – For a start-up or young business, going modular lets you minimize your initial investment. Once things are dialed-in and running smoothly, it’s easy to add additional capacity by simply replicating the first system.

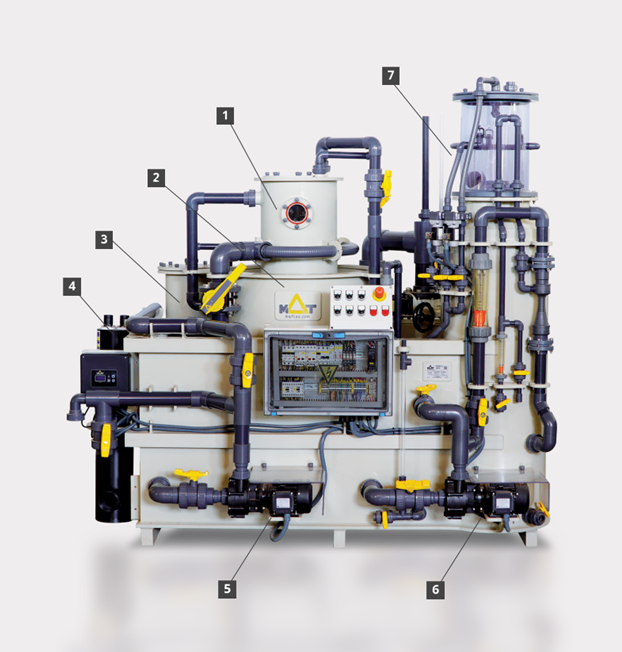

ADDITIONAL ADVANTAGES OF CONTAINERIZED COMPACT RAS STYSEMS

1. Advanced technology with strong in-house R & D team

2. Compact & Modular

3. PLC & SCADA options available for remote monitoring

4. Efficient, high-quality and scalable

5. 10 years warranty

6. Spare Parts package included

7. Components fully assembled and FAT tested

8. Plug & Play unit

9. Plant arrives ready for start-up

10. Turnkey solution: requires only connection to electricity, pipe & drain utilities.

ADVANTAGE AQUA FARMER

Well Trained aqua farmer can take advantage of

- Control of growing conditions: including temperature, water chemistry and turbidity, disease, etc.

- Growth cycles: including shortened time to harvest, size of the species, quality of product, as well as optimum harvest points and ability to plan for harvest.

- Better Feed to Biomass ratios: due to greater control of growing conditions and life cycles.

- Greater versatility: options for production location, nearness to market, marginal lands, etc.; ability to respond to demographic and consumer shifts.

- some systems are capable of growing different species – or can be easily transformed.

- Control of outputs and effluents: treatment and the possibility of reuse as fertilizer or input for other fish systems (in integrated aquaculture).

- Risk reduction: including climate, infection and disease, predation, etc.

- Reduction in direct operational costs: associated with feed and disease control from vaccinations and antibiotics.

- Greater fish intensity: better feed consumption and control of metabolic rates, less nutrient development from lost feed.

- Potential for ‘Clean product’: produced without hormones, antibiotics etc.; produced in environmentally friendly way; Green and Organic labeling.

- Potential for niche markets: either by species, availability (live to market), or size.

- Less area used and ability to use marginalized lands.

- Options for variable water sources

Challenges:

- Increase in capital costs: research and development is costly, system start‐up is higher.

- Increase in direct operational costs: oxygen inputs and maintaining chemical balances of the water, careful water monitoring, energy requirements, input output water treatment requirements.

- Complexity of technology.

- Risks: potential for rapid chemistry alterations resulting in dependency on monitoring.